November 25, 2024

As an important facility to enhance living comfort in modern homes, the material selection and installation process have a decisive impact on the final use effect. In many families pay more and more attention to the quality of life today, it is particularly important to understand the production materials and installation steps of the floor heating pad.

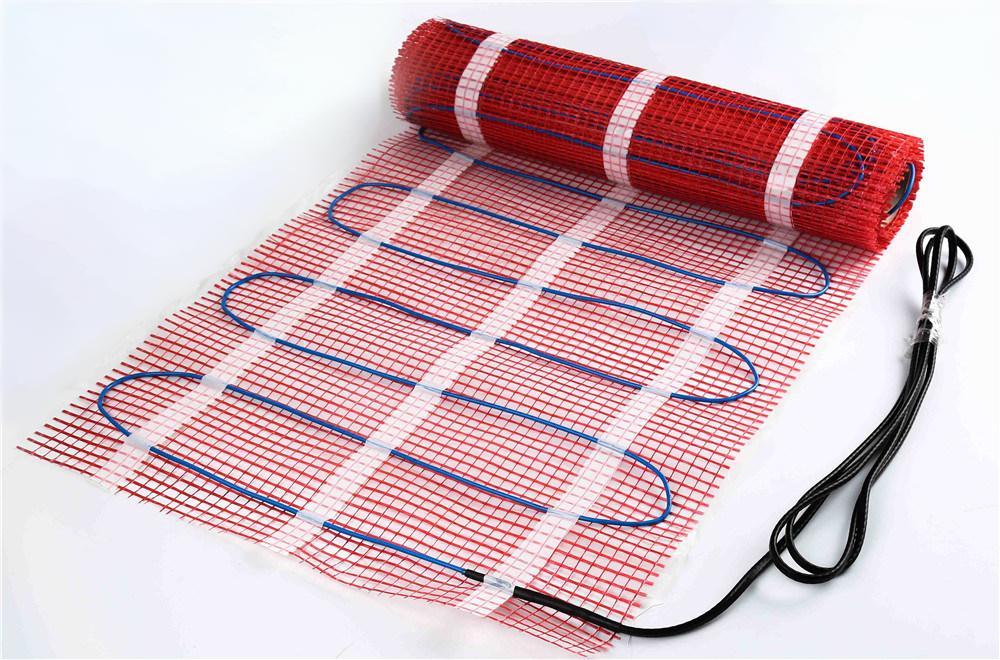

Floor heating pads are usually composed of conductive ink, graphene and insulating materials. As a special formula of silver oil, conductive ink not only has good electrical conductivity, but also has excellent adhesion and ductility, which ensures that the floor heating pad can evenly transfer heat during the heating process. Graphene, as a new material, has been widely used in the manufacture of floor heating MATS for its excellent thermal conductivity and stable chemical properties. Insulating materials are used to ensure the safety of use and prevent current leakage, common plastic materials such as PVC and PET.

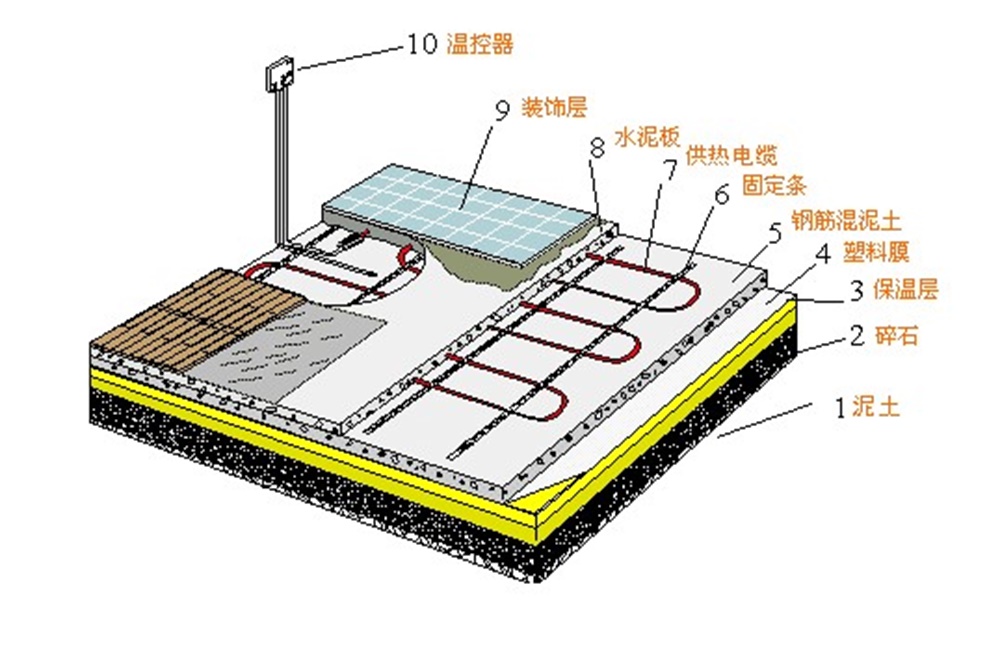

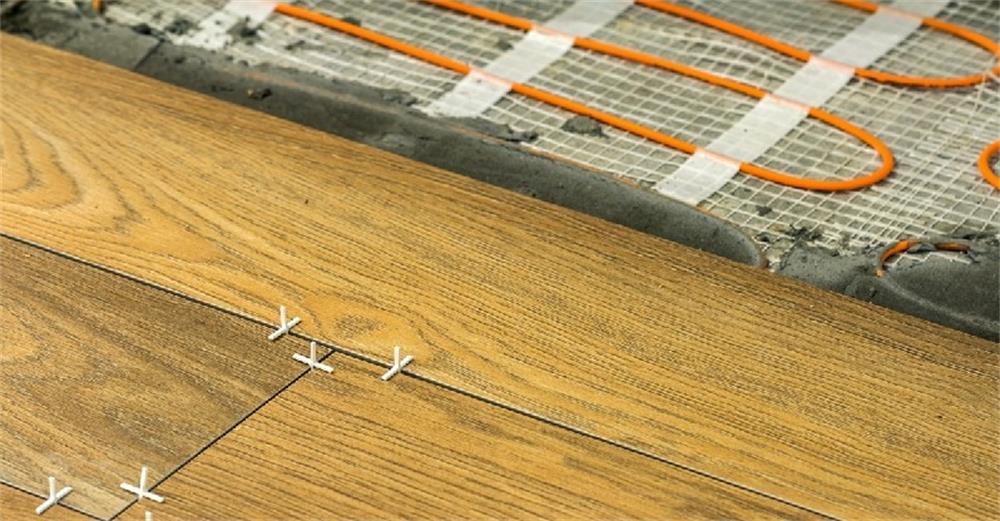

The process of installing underfloor heating is also crucial. The preparation before installation cannot be ignored. First, ensure that the floor of the room to be installed is smooth and clean, free of dust and water stains. Measure the specific size of the ground to determine the laying scheme of the floor heating pad. The next steps are specific installation steps. Lay the floor heating pad flat on the cleaned ground to ensure seamless docking between the MATS so as not to affect the heating effect. When connecting the power supply, you must follow the instructions of the product or professional electricians to ensure that the wiring is correct and the appropriate wire specifications are used. Debug the floor heating pad, adjust to the appropriate temperature, check whether the operation is normal, you can start to use after this step is completed.

It is worth mentioning that the maintenance of the floor heating pad is equally important. Regularly clean the dust on the surface of the floor heating pad to avoid sharp objects scratching the surface of the mat, these details will affect the service life and heating effect of the floor heating pad.

The production material of the floor heating pad determines its heating performance and service life, and the standardized installation process is the premise to ensure the normal operation of the floor heating pad. Through the understanding of the floor heating pad material and the correct installation and use, people can enjoy a warm and comfortable living environment in the cold season.